- CNC COMMUNICATION SOFTWARE HOW TO

- CNC COMMUNICATION SOFTWARE INSTALL

- CNC COMMUNICATION SOFTWARE MANUAL

- CNC COMMUNICATION SOFTWARE FULL

It uses g-code to send the necessary signals to your machine’s motors for it to perform tasks, whether that be drilling, cutting, engraving, or anything else. What is a CNC Controller?Ī CNC controller can be thought of as the “brain” of a CNC machine and forms the link between your computer system and your CNC machine’s mechanical components. We’ll then finish by taking a look at some of the finest hobbyist controllers on the market that you can buy today. We cover everything you need to know, including the different types of CNC controllers and how they work. That’s why we’ve created this ultimate guide to CNC controllers. This can make choosing the best controller for you somewhat tricky, particularly if you’re a beginner. The controller converts your g-code into the instructions the CNC machine uses to mill your final piece.ĬNC controllers are also one of, if not the most complex part of a CNC machine. 5-2ĥ.2.Whether you’re using a router, mill, lathe, plasma cutter, or laser cutter, a CNC controller is a vital component of any CNC machine. 5-1ĥ.2 Distribution Method with Redistribution Installer.

4-4Ĥ.5.1 Using OLE automation interface with VB. 4-3Ĥ.5 Overview of VB Programming of Automation Interface. 4-1Ĥ.2 Initialization for Enabling OLE/COM Interface.

CNC COMMUNICATION SOFTWARE MANUAL

Other company and product names that appear in this manual are trademarks or registered trademarks of theġ.1 Features. SD Logos are trademarks or registered trademarks of SD-3C, LLC in the United States, other countries or Microsoft Corporation in the United States and/or other countries.ĬompactFlash and CF are either trademarks or registered trademarks of SanDisk Corporation in the United Microsoft®, Windows, Visual C++® and Visual Basic® are either trademarks or registered trademarks of IE are either trademarks or registered trademarks of Mitsubishi Electric Corporation in Japan and/or otherĮthernet is a registered trademark of Xerox Corporation in the United States and/or other countries. MELDAS, MELSEC, EZSocket, EZMotion, iQ Platform, MELSOFT, GOT, CC-Link, CC-Link/LT and CC-Link Some functions may be different or unavailable depending on the version of the computerized numerical Operation error may cause machine damage or accident. Input error of setup or other parameter may cause accidental operation. Writing to the computerized numerical controller will directly be reflected in machine control. There is a risk of accident due to output error or malfunction.

CNC COMMUNICATION SOFTWARE INSTALL

Power supply failure and computer malfunction, and install the external safety circuit as fail-safe of the When connecting the product with the computerized numerical controller, consider the risk of external Keep this manual in a safe place for future reference. Important information that must always be observed is described. , may lead to major results depending on the situation.

When the user could be subject to medium or slight injuries or when physicalĭamage could occur if handling is mistaken. When there is a great risk that the user could be subject to fatalities or serious In this manual, the safety instruction levels are classified into "WARNING" and "CAUTION". Knowledge of general and safety information and precautions about the computerized numerical controller.

CNC COMMUNICATION SOFTWARE FULL

Do not use this product until you have a full The safety instructions in this manual are intended for this product. Read this manual before use to get familiar with and correctly use the functions of FCSB1224W000.īefore using the product, read the user's reference manual and other related manuals.

CNC COMMUNICATION SOFTWARE HOW TO

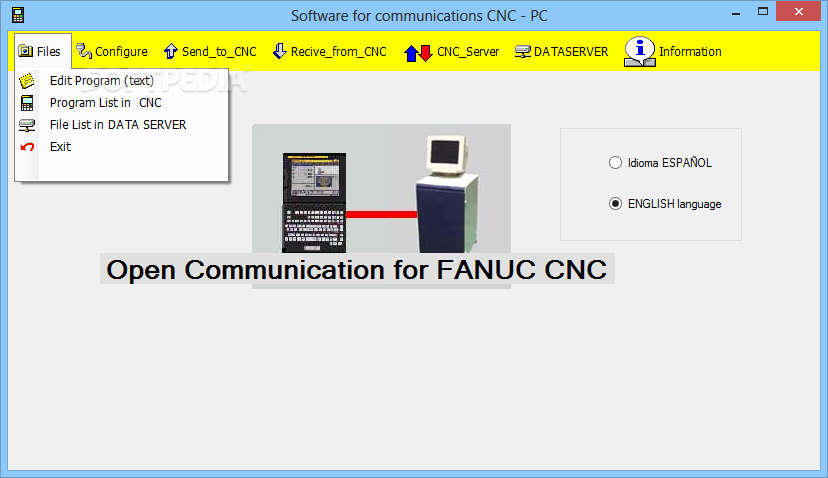

Reference manual describes how to use the OLE/COM interface of FCSB1224W000. Thank you for purchasing the Mitsubishi CNC communication software FCSB1224W000.

0 kommentar(er)

0 kommentar(er)